GC-2M84100B Double-Sided Grinder

Double Sided Grinding Machine can meet the requirements of high-precision surface grinding or fine grinding.

Item name: GC-2M84100B Double-Sided Grinder

Grinding Disc Size: φ1000xφ450×55, φ1000xφ350×55

Application: Used for processing hydraulic components, compressor parts, engine parts

Introduction

Crownkyn Superhard GC-2M84100B double-sided grinder can meet the requirements of high precision surface grinding or fine grinding, by removing the excess material on the two surfaces of the parts, can obtain extremely accurate geometric precision and surface finish. Usually, this is the last grinding step in the mechanical production chain to improve or correct the geometry of parts from sintering, sawing, molding or similar operations with an accuracy of 0.001m. Depending on the application, grinding from only one surface is also possible.

Widely used in double-sided precision grinding of automotive steering valve parts, refrigeration compressor parts, oil pump nozzle parts, engine parts, high-precision bearings, seals and other products.

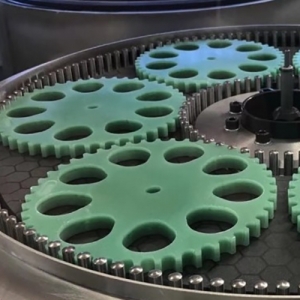

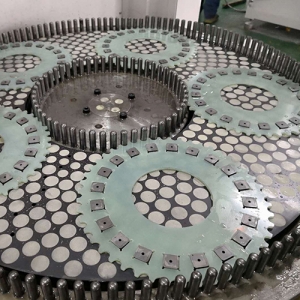

When the machine is working, the upper and lower grinding discs and the planet wheel rotate simultaneously to drive the workpiece to reciprocate between the two grinding discs. When grinding, you can use diamond grinding disc, CBN (cubic boron nitride) grinding disc, cast iron disc to process workpieces to meet the different requirements of various products, so as to achieve double-sided precision grinding on workpieces made of various materials.

Features

- Controlled by computer and numerical control system.

- Touch screen control interface, simple and intuitive, easy to operate

- High precision size and tolerance control.

- Equipped with constant temperature circulation cooling filter system.

- Powerful fault diagnosis function, timely and effective troubleshooting

- Grinding power over-limit alarm function

- Many choice functions, such as adjustment of processing technology, countdown, etc.

- Program data recording speed during processing

- Maintenance-free or less maintenance, extremely low operation cost

- Roughness ≤Ra0.05μm and flatness ≤0.001mm can be obtained with different abrasives and speeds.

- Unique processing technology and professional technical knowledge, tailor-made processing solutions for customers, improve production capacity.

Applications

1.Hydraulic components: vane pump, steering valve, plunger pump, gasoline pump, hydraulic motor, etc.

2.Compressor parts: air conditioner compressor blades, pistons, cylinders, refrigerator compressor valve plates, etc.

3.Engine parts: internal combustion chamber parts, booster pump parts, nozzle / pump parts, etc.

4.Others: carbide blades, high-precision bearings, seals, watch parts, ceramic valve cores, single crystal silicon wafers, magnetic materials and other products.

Technical Parameters

| Grinding Disc Size (mm) | φ1000xφ450×55, φ1000xφ350×55 |

| Maximum Processing Diameter (mm) | φ300 |

| Top Disc Motor Power (KW) | 7.5 ,11 |

| Top Disc Ration Speed (r / min) | 0~80 |

| Bottom Disk Motor Power (KW) | 7.5 ,11 |

| Bottom Disk Ration Speed (r / min) | 0~80 |

| Inner Ring MotorPower (KW) | 3 5.5 |

| Inner Ring Ration Speed (r / min) | 0~75 |

| Machine inlet Pressure (Pa) | 0.8MPa |

| Machine Tool Dimension LXBXH (mm) | 2170x2730x2760 |

| Machine Tool Weight (Kg) | 4500 |

| Typical Workpiece | Precision grinding of precision bearings, automotive parts, hydraulic parts, semiconductors and other non-metal parts |

| Parallelism (mm) | ≤0.001mm |

| Flatness (mm) | ≤0.001mm |

| Same Disc Isoheight Difference (mm) | ±0.001mm |

| Different Discs Isoheight difference (mm) | ±0.001mm |

| Surface Roughness (μm) | Ra0.05μm~Ra0.8μm |

| Control Method | PLC control, achieve 3, 5, 7 pressure control, automatic precision compensation |

| Measurement Method | Non-contact measurement, Contact measurement |