PCD End Mill

Item Name: PCD End Mill (PCD End Mill Blank)

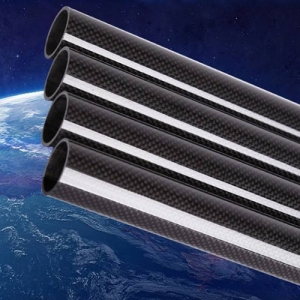

Material: carbide, PCD

Length: 60 mm, 75 mm, 100 mm (2.36 in)

Diameter: Min. 6 mm (0.236 in), Max. 25 mm (0.984 in)

Application: Cutting for aluminum, Carbon Fiber Reinforced Polymer/Plastic (CFRP), Acrylic, PVC, for the aerospace industry

Introduction

Crownkyn Superhard PCD milling cutter is a tool made by welding the PCD composite sheet (PCD bar stock) to the carbide or steel blade body using the “vacuum cladding single crystal brazing technology”. The high hardness, wear resistance and low friction coefficient of polycrystalline diamond are combined with the high bending strength of tungsten carbide cemented carbide. The tungsten carbide cemented carbide layer provides mechanical support for the diamond layer and increases its bending strength. The hard alloy layer is easy to weld and can produce PCD milling cutters of various shapes.

Crownkyn Superhard PCD milling cutters include PCD end mills, PCD T-slot milling cutters, internal R milling cutters, stone carving milling cutters, PCD ball nose milling cutters, acrylic carving milling cutters, PCD thread milling cutters. Non-standard customization can also be made according to the cutter pattern, and PCD milling cutter blanks are also provided.

Features

- The service life of the tool is super long, which is 20-100 times that of the common alloy tool, which saves the time occupied by frequent tool change and tool setting.

- Suitable for high-efficiency, high-speed (8000-40000 rpm), dry processing, it is the first choice for modern high-efficiency processing, no cutting fluid is used during processing, environmental protection and reliable.

- The blade is coated with TIAIN coating, which can directly perform high-speed roughing to fine processing on the heat-treated materials below 50 degrees, reducing the number of tool changes and increasing the machine tool utilization rate.

- The size of the parts is stable after processing. Due to the super wear resistance of the PCD material, the size of the tool is guaranteed to be unchanged during the processing of the part, and the size and shape tolerance of the processed workpiece are guaranteed.

- The surface roughness of the parts after machining is low, and the roughness of the products processed with PCD milling cutters can reach Ra0.8-Ra0.16, which can completely replace the traditional grinding process with milling and improve the processing efficiency and processing cost.

Applications

PCD end mill is suitable for processing aluminum, carbon fiber reinforced polymer / plastic, acrylic, PVC and other difficult-to-process materials.