Grinding discs are collectively referred to as tools that perform the functions of grinding and polishing in the machining process. Grinding discs can be divided into natural grinding discs and man-made grinding discs according to the source of their raw materials. With the continuous development of industry and technology, the proportion of natural abrasive discs in the abrasive discs is becoming less and less. The only natural abrasive discs used in the modern machinery industry are oilstone. According to its basic shape and structural characteristics, artificial grinding discs are mainly divided into three categories: consolidated grinding discs, coated grinding discs and grinding pastes.

The successful development of the ceramic bond CBN grinding disc has made CBN grinding discs widely used in grinding processing, especially in forming grinding and mass production. The application of ceramic bond CBN grinding discs in industrially developed countries have expanded from difficult-to-machine materials to general materials, from general grinding (internal and external circular grinding) to forming grinding, centerless grinding, slow-feed grinding, and precision grinding, High-speed grinding, honing and other types of grinding, the application field involves tools, cutting tools, bearings, automobiles, ships, machine tools, aerospace, military and other industrial fields. Although the domestic ceramic bond CBN grinding disc preparation technology is also developing rapidly, the research system is still incomplete due to its late starting, especially in terms of product technology, high-end product performance, and new product development of CBN grinding discs. Considerable gap, most of the high-end products used are imported. With the continuous improvement of modern industrial machining requirements and increasing demand, domestic research on ceramic bond CBN abrasive discs has become more and more important.

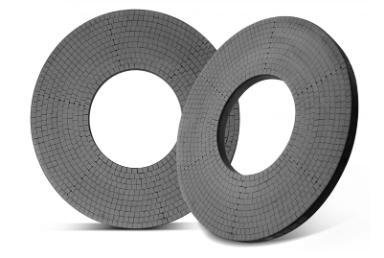

Among the CBN grinding discs of various bonding agents, the ceramic bonded CBN grinding discs have sharp cutting, low cutting force, high production efficiency, good shape retention of the wheel, high durability, adjustable air holes, non-clogging during grinding, and It has the advantages of shaping and trimming, high grinding accuracy. And also has the characteristics of low workpiece grinding temperature, can eliminate the surface tensile stress and generate residual compressive stress, which improves the durability of the workpiece by 30% to 50%. When applied to double-end grinding, its high metal removal rate results in fewer burns. At the same time, it can maintain the flatness, parallelism and dimensional accuracy of the workpiece for a long time, improve production efficiency, and reduce overall grinding cost. Therefore, as a kind of high-speed, high-efficiency, high-precision, low-grinding cost, and low environmental pollution high-performance grinding disc products, ceramic bond CBN grinding discs have broad development prospects in the field of double-end grinding.

Crownkyn

Crownkyn Crownkyn

Crownkyn Crownkyn

Crownkyn