CBN is synthesized from hexagonal boron nitride and a catalyst under high temperature and pressure, and its properties are similar to those of synthetic diamond, and some properties (such as thermal stability) are better than diamond. It has high hardness, thermal stability and chemical inertness, as well as excellent infrared transmittance and wide forbidden band width. Its hardness is second only to diamond, but its thermal stability is much higher than diamond, and it has great chemical stability for processing iron metallic elements.

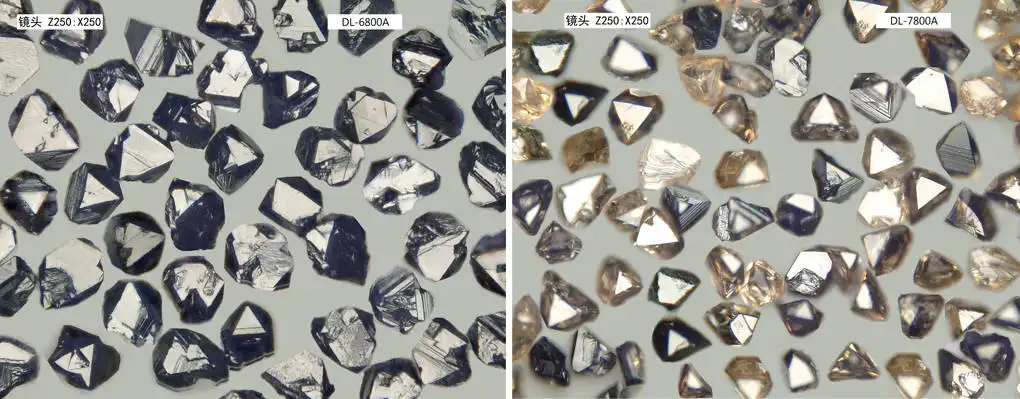

The grinding performance of cubic boron nitride(CBN) abrasives is very good, not only can it be competent for the processing of difficult-to-grind materials, but also effectively improve the grinding quality of workpieces.

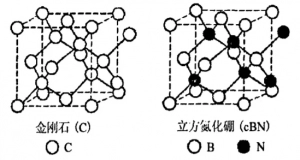

Crystal structure of CBN

- The Performance of CBN Powder

1.1 Hardness

The hardness of a substance is related to the atomic spacing of the constituent lattice, and as the atomic spacing decreases, the crystal hardness increases. CBN is 1.57 angstroms, and the shortest distance between diamond atoms is 1.5 angstroms. Therefore, the hardness of CBN (microhardness 71.54GP) is slightly lower than that of diamond powder, but higher than that of the other two main abrasives, silicon carbide (Sic-microhardness 25.48~35.28GPa) and alumina (Al₂O₃-microhardness 17.64~27.44GPa) is much higher.

Using a Knoop hardness tester, the hardness of CBN single crystal in the [100] direction is 4600kg/mm², while that of the diamond is 10000kg/mm². The hardness of CBN single crystal in the [110] direction is 3200kg/mm², while that of the diamond is 7000kg/mm². This shows that the hardness of CBN is anisotropic, and its hardness is slightly lower than that of the synthetic diamond powder.

The superhard materials previously used in production mainly refer to diamond powder and cubic boron nitride powder. Cubic boron nitride and cubic diamond have a common feature that the covalent bond “bond angle” in their structure is 109°28′. It is the 109°28′ covalent bond angle that makes cubic boron nitride and cubic diamond have the highest hardness and is called superhard material.

1.2 Thermal conductivity

Cubic boron nitride has good thermal conductivity. Its thermal conductivity (79.54wm·k) is smaller than that of diamond (146.5w/m·k), but much higher than that of high-speed steel (16.7~25.1w/m·k) and Carbide (20.33~80.77wm·k). With the increase of cutting speed, the thermal conductivity of CBN also increases gradually, which is beneficial to reduce the temperature of the cutting zone and reducing

diffusion wear. At the same time, due to the good thermal conductivity of CBN, its efficacy as a heat sink is second only to that of industrial diamond powder.

1.3 Thermal stability and oxidation resistance

Cubic boron nitride has high thermal stability and can withstand cutting temperatures above 1200 ° C, which is better than diamond. Cubic boron nitride has high hardness and high thermal stability and can be used as a high temperature-resistant material to reduce thermal damage to the workpiece.

The heat resistance of cubic boron nitride is mainly determined by its composition and structure. Although cubic boron nitride has a similar structure to diamond, the carbon atom bonds on the diamond surface are unsaturated. Under the condition of high temperatures above 720 °C, these unsaturated surface carbon atoms are easily combined with oxygen atoms to form carbon oxides and escape. The crystals are gradually peeled off and disintegrated. The surface of the cubic boron nitride crystal is covered by nitrogen and boron atoms, and the electronic layer structure of the boron atom is 1S22S22P1, which can provide three bonding electrons, so that the valence bond of the boron atom on the crystal surface is saturated without dangling bonds, so It is still relatively thermally stable at the diamond oxidation temperature.

Therefore, CBN has high anti-oxidation ability, and no oxidation phenomenon occurs at 1000 °C. In vacuum, the phase transition from CBN to HBN occurs when the temperature reaches 1550 °C.

1.4 Chemically inert

CBN is chemically inert and has high chemical stability to acids and bases in neutral and reducing gas media.

CBN is also chemically resistant to iron, steel and oxidizing environments, forming a thin layer of boron oxide when oxidized. This oxide provides chemical stability to the coating, so it is especially suitable for processing ferrous materials. On the other hand, diamond is different. Steel and iron have a large affinity for carbon, so it is easy to stick chips during grinding, resulting in poor grinding effect.

1.5 Disadvantages of single crystal cubic boron nitride (CBN)

In addition to the above advantages, the single crystal cubic boron nitride grains have the disadvantages of small size and anisotropy, cleavage planes that are easy to split, and high brittleness, which is extremely prone to cleavage damage.

2. The Application of cubic boron nitride (CBN)

Due to its poor compatibility with iron group metals and alloys, cubic boron nitride (CBN) is one of the main tools for processing iron group hard and ductile materials. At present, cubic boron nitride is mainly used in the production of abrasives and PCBN cutting tools.

2.1 Small particle CBN single crystal is mainly used as the abrasive material.

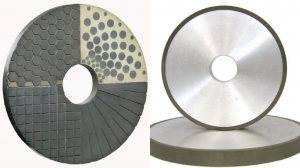

CBN abrasives are products with specific geometric shapes that bond CBN abrasive grains with the help of binders. As a kind of superhard material abrasive tool, CBN abrasive tool is used for grinding, which belongs to the emerging advanced manufacturing technology. It can be used for the processing of iron-based materials and non-ferrous metal materials. The application range of the field is wider than that of diamond abrasive tools.

The cubie Boron Nitride abrasive tool has good grinding performance for ferrous metals, especially for materials with high hardness, toughness, high strength and low thermal conductivity at high temperature, and its metal grinding rate is 10 times that of diamond, which solves the problem of processing hard and tough materials. The cubic boron nitride grinding tool is used in high-speed and efficient grinding and honing, which can greatly improve the grinding efficiency. It has high grinding precision, long grinding wheel life and saves much auxiliary time such as grinding wheel replacement dressing, machine tool adjustment and workpiece inspection.

CBN Grinding Disc and Wheel

2.2 CBN can also be used as cutting tools

CBN can also be used as cutting tools, such as drills, turning tools, reamers, and milling cutters, which are used to process tool steel including high-speed steel and die steel, bearing steel, stainless steel, nickel-based alloys and chilled hardened cast iron. In these processing fields, CBN replaces corundum and has achieved good economic results. Especially when processing cemented carbide steel above HRC50, because CBN is sharper than corundum and has more stable performance than diamond, it shows a series of advantages.

PCBN Cutter